|

AutoSoft Systems | ||||||||||||||||||||||||||||||

| AutoSoft Systems | 2 Round Hill Court | ||||||||||||||||||||||||||||||

| East Greenwich, RI 02818 | |||||||||||||||||||||||||||||||

| 401.885.3631 | |||||||||||||||||||||||||||||||

| 401.884.5653 Fax | |||||||||||||||||||||||||||||||

| 401.996.3631 Cell | |||||||||||||||||||||||||||||||

| AMDG | Decision Ready Information! | autosoft@aol.com | |||||||||||||||||||||||||||||

| Commercial & custom multi-user computer software for a variety of applications including performance metrics, statistical analysis, data extraction and merger from multiple large databases, computer simulation and management information systems. Founded in 1982. | |||||||||||||||||||||||||||||||

| We know Excel! Whenever possible, Excel is the user interface, VBA is the programming language, ODBC connects to the database of your choice. | |||||||||||||||||||||||||||||||

| Home | About Us | Literature | Wire & Cable | Pharmaceutical & Biotech | Construction Management | Commercial Products | Custom Solutions | ||||||||||||||||||||||||

| Contact Us | Events | Downloads | |||||||||||||||||||||||||||||

| AMDG | |||||||||||||||||||||||||||||||

![MCBS00913_0000[1]](maximo_files/index_0000_image004.png)

|

|||||||||||||||||||||||||||||||

| "IBM MaximoŽ Asset Management unifies comprehensive asset life cycle and maintenance management on a single platform." | |||||||||||||||||||||||||||||||

| From IBM's web page: | http://www-01.ibm.com/software/tivoli/products/maximo-asset-mgmt/ | ||||||||||||||||||||||||||||||

| MaximoŽ is a trademark of IBM | |||||||||||||||||||||||||||||||

| TrackwiseŽ is a trademark of Sparta Systems | |||||||||||||||||||||||||||||||

| AutoSoft is not affiliated with neither Sparta Systems nor IBM. | |||||||||||||||||||||||||||||||

| MaximoŽ is indeed a powerful tool. It is a tremendous repository of valuable information regarding asset management for large multinational corporations. AutoSoft has provided a number of Excel-VBA-ODBC/ADO (Visual Basic for Applications, Open Data Base Connectivity, Active Data Objects) solutions that have eliminated human error and tedium of running reports as well a eliminated up to 95% of the work associated with the generation of these reports. It is important to note that Excel-VBA-ODBC/ADO access directly into MaximoŽ is READ-ONLY. This assures the integrity of the MaximoŽ database, which is imperative. | |||||||||||||||||||||||||||||||

| Note, these examples are just some of the ways that AutoSoft has helped improve asset life cycle management through "tuning" of the MaximoŽ data base. The possibilities for Excel-VBA-ODBC/ADO reporting is endless. We are only limited by our imaginations. In all cases, Maintenance Managers identified the need for a report, and worked with Dr. Serdakowski to prepare the specifications for the report. Dr. Serdakowski then worked his "magic" to prepare the reports as specified. | |||||||||||||||||||||||||||||||

| All examples here share one or more of the following common motivations: | |||||||||||||||||||||||||||||||

| ● | Improve visibility to exceptions in the MaximoŽ database to improve accuracy and avoid compliance issues | ||||||||||||||||||||||||||||||

| ● | Reduce the clerical time to generate reports by increasing the automation in report generation | ||||||||||||||||||||||||||||||

| ● | Provide reports in the most versatile format available - Excel | ||||||||||||||||||||||||||||||

| ● | Reduce the cost of maintenance | ||||||||||||||||||||||||||||||

| ● | Make report generation easier for the user who is not a computer expert | ||||||||||||||||||||||||||||||

| ● | Make report generation easier for the seasoned programmer | ||||||||||||||||||||||||||||||

| ● | Provide "tickler" emails to system owners to remind them to complete upcoming or tardy tasks | ||||||||||||||||||||||||||||||

| ● | Save Time, Save Money, Improve Accuracy | ||||||||||||||||||||||||||||||

| Examples: | |||||||||||||||||||||||||||||||

| Work Order Scheduling | Let's face it, scheduling a bunch of work orders in Maximo is a bit of a chore. There are only a limited number of hours in a work day, and filling up a technician's work load without leaving idle time or overloading is difficult and time consuming. AutoSoft Systems has solved this problem and guarantees to get your Work Order Planners home on time. | ||||||||||||||||||||||||||||||

| Planner & Buyer Report | Planners and Buyers are tasked with assuring that all necessary spare parts are stocked in the warehouse when required BUT do not overstock items. This report provides the Planners and Buyers with the "Decision Ready Information" to optimize inventory levels. | ||||||||||||||||||||||||||||||

| The MATRIX | This tool is a universal search and retrieval tool that can simultaneously search the Maximo and other corporate databases (including Trackwise) for key words. Results are achieved in seconds! Potential annual times savings at major corporations can easily exceed 1 million dollars. Corporate databases are good at getting information into them, but leave much to be desired when you need to find something. Typically, you have to search one database at a time. The MATRIX does it all for you. | ||||||||||||||||||||||||||||||

| Mean Time Between Maintenance | This tool looks at all work orders in MaximoŽ, and allows the user to slice and dice the data by 20 different parameters (i.e. Start Date, Work Type, Site, System Description, .). Once the user defines the subset that is to be analyzed, a stand-alone workbook containing all of the pertinent records is generated. In addition to a detailed listing of all workorders matching the filter criteria, one can perform Pareto analysis by Site, Building, System and Sub-System based on # of Events or $$$ spent. Pareto charts can also be generated. | ||||||||||||||||||||||||||||||

| Mean Time Between Failures | Let's face it. Equipment breaks. Often at the worst possible time. Some equipment breaks more often than others. MaximoŽ has stored in it a huge treasure-trove of information. Getting it out sometimes seems more difficult than getting gold out of sea water. AutoSoft's Mean Time Between Failure tool calculates just that for all equipment stored in Maximo. This is a pre-compiled program, meaning the program pre-processes the necessary information overnight, resulting in a quick and easy user interface that gets you the answers quick. | ||||||||||||||||||||||||||||||

| Preventative Maintenance Forecasting Tool | Preventive Maintenance (PM) is the key to a smooth running operation. MaximoŽ has very powerful PM capabilities, but it is a bit of a chore to get a good handle as to the future requirements to support the PM efforts. This tool dramatically assists in that task. | ||||||||||||||||||||||||||||||

| Maximo Metrics Reporting | "What gets measured gets

managed." Dashboards are key to being able to track performance of an operation. This process can become extremely granular. AutoSoft Systems has prepared a customized dashboard for a major pharmaceutical manufacturer that measures a myriad of metrics across the entire corporate. |

||||||||||||||||||||||||||||||

| Late Preventative Maintenance Notification Tool | This tool scans the Maximo database and culls out PM workorders that are overdue or soon to be overdue. The owner of each work order is identified, and an email is sent to each owner warning him/her. This utility can be set up to run automatically at whatever frequency is desired. | ||||||||||||||||||||||||||||||

| Assets / Parts Report | This tool lists all Assets and Spare Parts associated with each Asset. Also indicates if the average cost of each spare part and the annual site usage for the current year and prior 3 years. | ||||||||||||||||||||||||||||||

| Click here to download an example of this report | |||||||||||||||||||||||||||||||

| Asset Spare Parts Email Reminder | This tool performs a query into the Maximo

Database, returning records that are within 21 days of, or beyond the

deadline for owner action. The tool

will send out emails to each owner, clustering all records for each owner

into one email. Records will be

included in the email if the

deadline is 21, 14, 4,3,2,1,0 days

away or if the deadline has passed. |

||||||||||||||||||||||||||||||

| Future PM Cost Calculator | This program mines data from Maximo to estimate the cost of future preventative maintenance costs. It also isolates PM related inconsistencies in the Maximo data base to facilitate corrections. | ||||||||||||||||||||||||||||||

| Maximo Data Scrubber | This program combs through the Maximo database and isolates 5 defined exceptions and 2 specific database changes. It automatically sends emails to the system owners, notifying them of the exceptions and "encouraging" them to make corrections. The number of exceptions are trended with time so that progress can be tracked. | ||||||||||||||||||||||||||||||

| Subsystem Analysis Workbook | The program assists system owners in optimizing Preventative Maintenance frequencies and costs. | ||||||||||||||||||||||||||||||

| TrackwiseŽ - MaximoŽ Data Synchronization | Non-conformances continue to exist despite everyone's best efforts. Accurate and complete documentation of each and every NC is of paramount performance. Some NCs are related to process equipment and/or have a "Machinery" root cause classification. Text entry fields in Trackwise allow the NC owner to record the equipment and the system associated with equipment and/or machinery related NCs. There is no mechanism in Trackwise to validate that the equipment or system entered is indeed a valid Maximo entry. AutoSoft can! | ||||||||||||||||||||||||||||||

| One Report Containing MaximoŽ & TrackwiseŽ Data | Don't you just love it. Corporations today have software tools for all different functions, however getting them to talk to each other is difficult to say the least. Recently, Dr. Serdakowski was asked by an existing client to develop one report that would automatically extract data from both the MaximoŽ and TrackwiseŽ databases. Dr. Serdakowski delivered the finished product in less than one hour. Here is an outline of how it works. | ||||||||||||||||||||||||||||||

| Data Dictionary Generator | The Maximo database comprises approximately 400 tables and views and in excess of 14,000 total fields. This tool provides lists of the tables and associated fields, as well as "clones" each table into a stand-alone Excel workbook (at least the first 65,533 records for large tables in Excel 2003 and 1,048,574 records in Excel 2007), putting the entire Maximo table structure and content at your fingertips! This tool is a great time saver for any programmer looking to generates reports out of Maximo. | ||||||||||||||||||||||||||||||

| Weekly Snapshot | This

is an email that is sent weekly to a designated list providing a dashboard of

metrics. Some examples: - Work Orders older than 90 days - Work Orders by Craft (aging) - Backlog by Craft |

||||||||||||||||||||||||||||||

| Asset Calibration Ranges | This report lists all of the calbration paramters for all calibrated Assets | ||||||||||||||||||||||||||||||

| Asset Report | Lists

all Assets along with their dozens of properties including: - Location - Ower - Failure Code - Asset Class |

||||||||||||||||||||||||||||||

| Buyer / Planner Report | Provdies

a summary of all work orders requiring spare parts, and alerts the Buyers and

Planners to what - parts are in inventory - parts that have been ordered and not yet received - parts that need to be ordered to complete the scheduled work orders. |

||||||||||||||||||||||||||||||

| CE & CC Work Order Report | Provides a list of all CC and CE Work orders that have been scheduled and their statuses. Links the work orders to child work orders when appropriate. Provides details notes and allows the users to make further comments about each work order. | ||||||||||||||||||||||||||||||

| Job Plan Status and Waiting Report | Lists Job Plans that are being revised. Lists the number of days each Job Plan has been undergoing revision. Emails people alerting them if the revision has been "sitting on their desk" for an excessive period of time. | ||||||||||||||||||||||||||||||

| Labor Groups Report | Lists all Labor Groups and personnel assigned to each | ||||||||||||||||||||||||||||||

| Locations Report | List

all Locations in Maximo along with many key properties including: - Description - Parent - Status - Owner |

||||||||||||||||||||||||||||||

| Workorder Waiting Attachment report | List all work orders that are waiting attachments, the duration that they have been waiting, with an option to email the person responsible for the attachment and the person's supervisor in the case of the wait being excessive. | ||||||||||||||||||||||||||||||

| Schedule Adherance Tool | This application identifies work orders that were not completed on time and provides the work order owners the opportunity to explain why the work order was late. The tool then compiles the results into a series of dashboards and metrics to allow management to track the performance of the work order administration department. | ||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

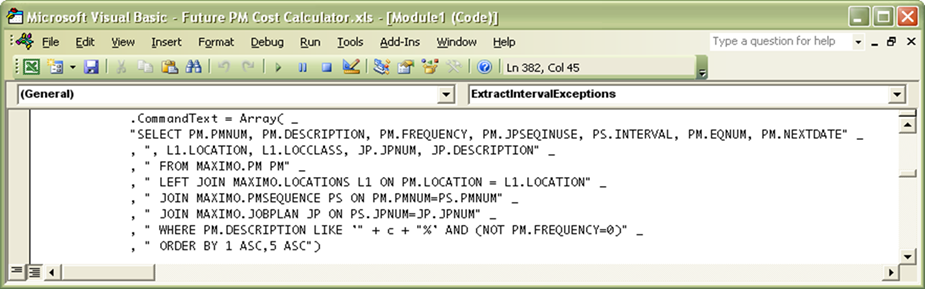

| An example of the VBA code that harvests data from Maximo: | |||||||||||||||||||||||||||||||

| AutoSoft Systems | 2 Round Hill Court, East Greenwich, Rhode Island, USA 02818 | 401.885.3631 | Fax: 401.884.5653 | Mobile: 401.996.3631 | |||||||||||||||||||||||||||||||

| This web page was last updated at 01/09/2024 04:51 PM and is written in EXCEL! | |||||||||||||||||||||||||||||||

| AXIOM is a Trademark of Consona - USYS is a Trademark of Zumbach - AutoSoft Systems is not affiliated with Consona nor Zumbach | |||||||||||||||||||||||||||||||