|

|

|

|

|

|

|

|

|

|

|

|

AutoSoft Systems |

| |

|

|

|

AutoSoft

Systems |

2 Round Hill

Court |

| |

|

|

|

East Greenwich,

RI 02818 |

| |

|

|

|

401.885.3631 |

| |

|

|

|

401.884.5653 Fax |

| |

|

|

|

|

|

|

|

|

|

|

|

401.996.3631 Cell |

| AMDG |

|

|

|

Decision Ready

Information! |

autosoft@aol.com |

| Commercial & custom multi-user computer software for a

variety of applications including performance metrics, statistical analysis,

data extraction and merger from multiple large databases, computer simulation

and management information systems.

Founded in 1982. |

| We know Excel! Whenever possible, Excel

is the user interface, VBA is the programming language, ODBC connects to the

database of your choice. |

| Home |

About Us |

Literature |

Wire

& Cable |

Pharmaceutical

& Biotech |

Construction

Management |

Commercial

Products |

Custom Solutions |

| Contact Us |

Events |

Downloads |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AMDG |

![MCHH01465_0000[1]](datascrubber_files/index_0000_image004.png)

|

| Maximo® is a

trademark of IBM |

| AutoSoft is

not affiliated with IBM. |

| This program combs through the Maximo database and isolates 5

defined exceptions and 2 specific database changes. It automatically sends emails to the system

owners, notifying them of the exceptions and "encouraging" them to

make corrections. The number of

exceptions is trended with time so that progress can be tracked. |

| It is important to note that this entire program was written by

Dr. Serdakowski in less than 80 hours. In this case, the Corporate Facilities

and Engineering Manager had a clear vision for what was needed and

communicated his vision to Dr. Serdakowski.

This type of detailed analysis is virtually impossible with

conventional Maximo reporting tools such as Brio, which is a very effective

tool for "one-up" queries but cannot be automated. |

| Maximo data is constantly changing, with new errors being

introduced. Significant errors lead to

operational difficulties, increased costs and possible compliance

issues. The Data Scrubber will catch

and correct problems as they are generated. This process is considered a

business procedure, not an SOP procedure which would require a higher level

of management. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The 5 defined exceptions are: |

| ● |

Classification

Adherence - The primary location for the asset is level 1. A list of equipment for each system has

been compiled. For example, a chilled

water system would have in its list items like: Air Separator, Blackflow

Preventer, Chiller, Compressor, Control Panel …. None of these items should be classified as

"Level 1". If one is, then

an exception is noted. |

| ● |

The asset is in

an incorrect system - Sometimes a piece of equipment will be included in a

system incorrectly. For example, a Transformer should not be included in a

Chilled Water system. |

| ● |

Hierarchy

Adherence - The asset's first 10 digits of its primary location are not same

as the subsystem - this is to assure the parent-child relationship is well

defined in the Maximo database.

Exceptions to this rule are identified. |

| ● |

Spares - The

asset exists in the system. These

specified items should not exist in the system, but should be considered

spare parts. Again, for a Chilled

Water system, items like Motor, Starter, Strainer… would be classified as

such. If a listed item appears in a

system, an exception is noted. |

| ● |

Nomenclature -

The equipment description does not equal anything on the list. This

identifies equipment added to a system that does not belong there. |

| The 2 specific database changes are: |

| ● |

Classification

Level 1 to Classification Level 2 in the last 30 days |

| ● |

Classification

Level 2 to Classification Level 1 in the last 30 days |

| The main screen looks like: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Help is available at the touch of a

button: |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Significant pre-work was performed by the engineer in charge of

this scrubbing to identify the corporate systems and what pieces of equipment

need to be included and excluded in each system. All of this information was

compiled into an Excel workbook with a worksheet for each system. The light blue button on the main screen

allows the user to select the document and begin the process. An import log (cell B4 above) records the name

of the imported file and the date of the import. |

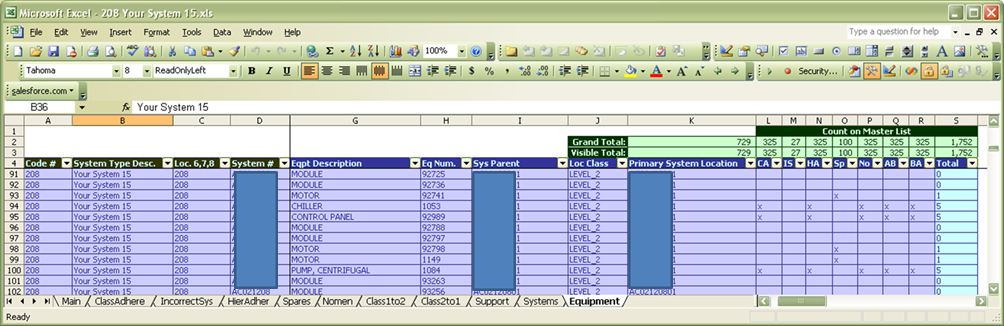

| For example, Row 22 above, lists in cells C22:I22 the number of

entries for that system in each of the 7 categories searched. Cell L22 tells us that there are 81 systems

of this type corporate-wide with 729 associated pieces of equipment. There are 393 total exceptions (U23) 100 of

which are spare parts that are incorrectly placed in the system (Q23). Double clicking on cell A22 opens a stand-alone

Excel workbook with details of the exceptions. The main screen summarizes the 81 systems

and the count of each problem for each system: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| There are 7 worksheets which give specifics on each exception: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The System worksheet lists all systems and the names and emails

of each system owner: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

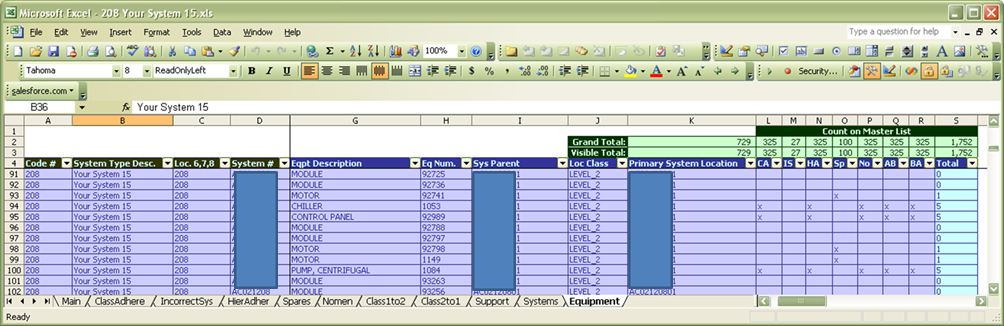

| The Equipment worksheet lists all of the equipment in all

systems of this type: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

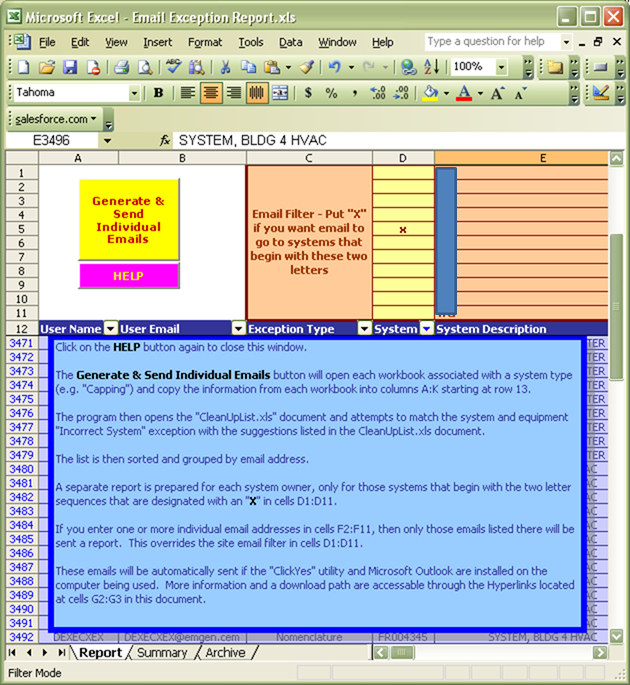

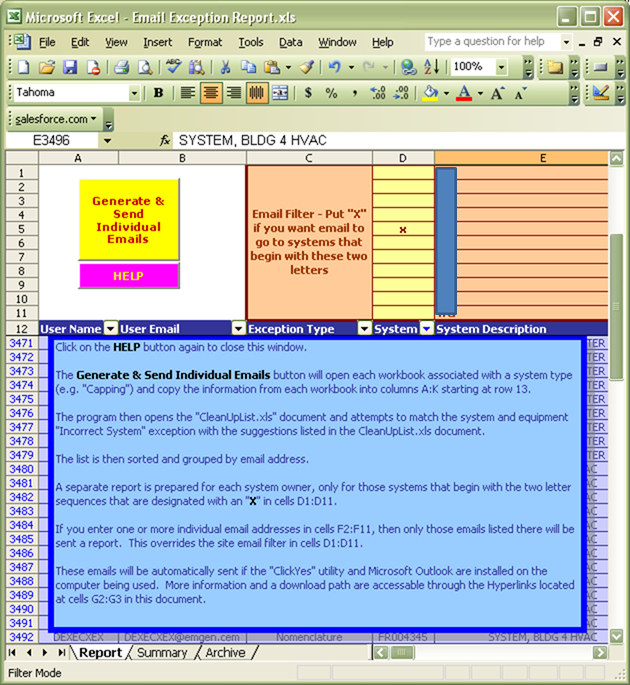

| The email utility is quite powerful. It will automatically send out emails to

all system owners (or a specified subset) that will alert them to exceptions

in their systems as well as offer suggestions as to how to correct the

exceptions. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Again, Help is just a click away: |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Performance metrics are generated in the form of a trend

chart. One can simply track the number

of exceptions for a selected system or the database as a whole using the

Archive worksheet. Trend Charts are

generated with a simple mouse click: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| AutoSoft Systems | 2 Round Hill Court, East

Greenwich, Rhode Island, USA 02818 | 401.885.3631 | Fax: 401.884.5653 |

Mobile: 401.996.3631 |

| This web page was last updated at 02/21/2014 07:52 AM and is

written in EXCEL! |

| AXIOM is a Trademark of Consona - USYS is a Trademark of Zumbach

- AutoSoft Systems is not affiliated with Consona nor Zumbach |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![MCHH01465_0000[1]](datascrubber_files/index_0000_image004.png)