|

|

|

|

|

|

|

|

|

|

|

|

AutoSoft Systems |

| |

|

|

|

AutoSoft

Systems |

2 Round Hill

Court |

| |

|

|

|

East Greenwich,

RI 02818 |

| |

|

|

|

401.885.3631 |

| |

|

|

|

401.884.5653 Fax |

| |

|

|

|

|

|

|

|

|

|

|

|

401.996.3631 Cell |

| AMDG |

|

|

|

Decision Ready

Information! |

autosoft@aol.com |

| Commercial & custom multi-user computer software for a

variety of applications including performance metrics, statistical analysis,

data extraction and merger from multiple large databases, computer simulation

and management information systems.

Founded in 1982. |

| We know Excel! Whenever possible, Excel

is the user interface, VBA is the programming language, ODBC connects to the

database of your choice. |

| Home |

About Us |

Literature |

Wire

& Cable |

Pharmaceutical

& Biotech |

Construction

Management |

Commercial

Products |

Custom Solutions |

| Contact Us |

Events |

Downloads |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AMDG |

![MCPE01984_0000[1]](subsystem_files/index_0000_image004.png)

|

| Maximo® is a

trademark of IBM |

| AutoSoft is

not affiliated with IBM. |

| In these trying economic times, corporations are looking high

and low for savings. One candidate is

the cost of Preventative Maintenance.

It is a time consuming task to review each and every subsystem in a

corporation and validate that all necessary maintenance is being performed,

but excessive maintenance is not. A

Senior Maintenance Engineer defined a methodology to be applied by all system

owners corporate-wide to assess their maintenance costs with the goal of

adjusting the maintenance procedures and schedules to optimize both costs and

effectiveness. His methodology was

quite extensive, and required multiple Brio queries and reports to conduct

this comprehensive assessment. The

initial implementation was a failure because the queries were difficult to

properly configure, transferring the query results from Brio to Excel was

tedious and time consuming, and once the data was in Excel, the analysis was

exacting and subjective. |

| It is important to note that this entire program was written and

revised up to Version 17 by Dr. Serdakowski in less than 80 hours. |

| In this case, the Maintenance Engineer communicated his

methodology to Dr. Serdakowski. The

final product resulted in a 95% labor savings compared against the initial

procedure using conventional Maximo reporting tools (Brio) and manually

transferring the results to Excel. The

version illustrated below has been implemented across the entire corporation

at multiple sites in multiple countries. |

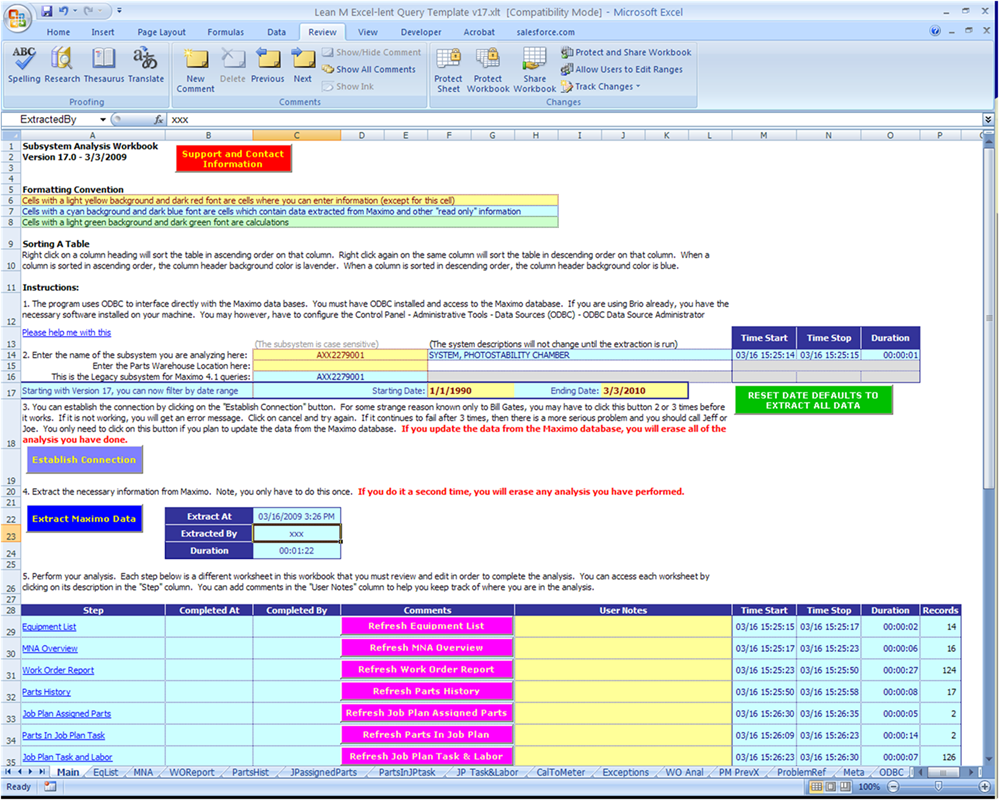

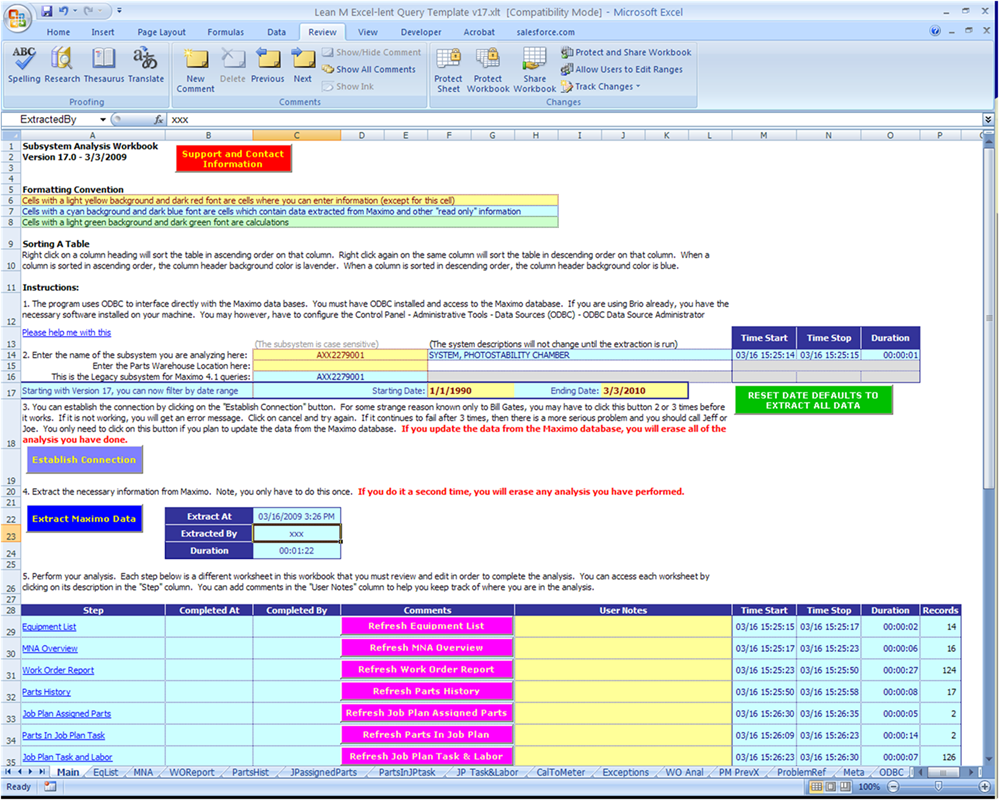

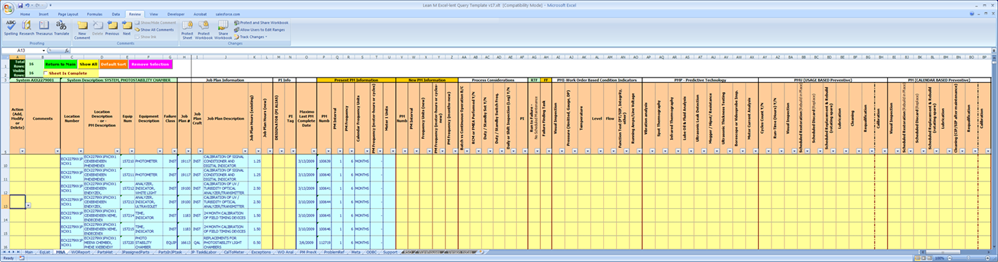

| This workbook follows the standard AutoSoft conventions. Any cell with a YELLOW background is a cell

where the user can enter information. The document is fully protected so the

user can ONLY enter information in the yellow cells. The main screen looks

like: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

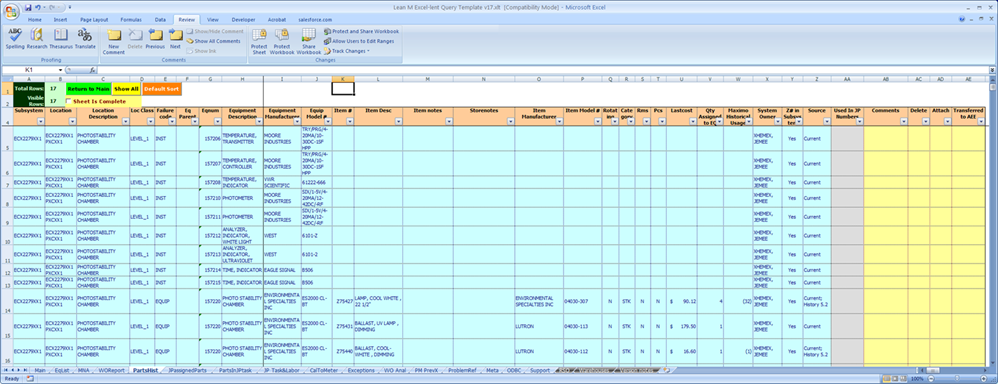

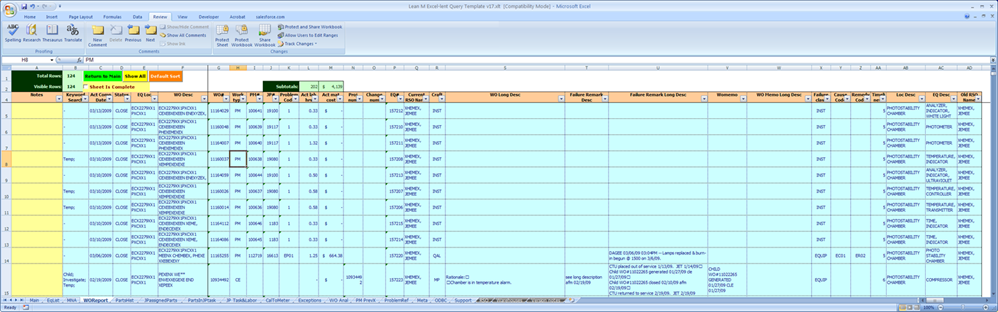

| Simply enter the subsystem and click the BLUE button, the

program does the rest. First, an

equipment list is generated: |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

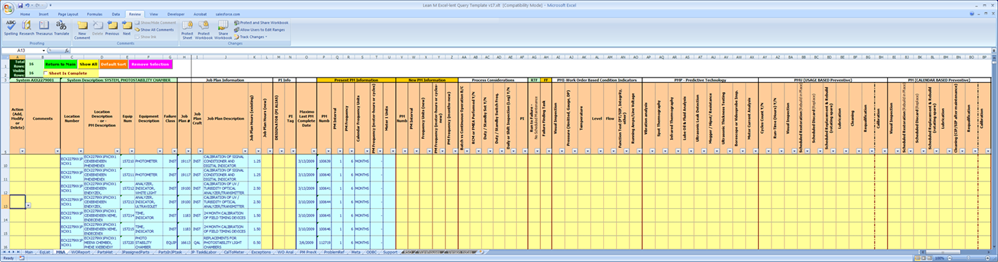

| The MNA (Maintenance Needs Assessment) worksheet is the next one

populated. This one is very

comprehensive and seems to go on forever: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

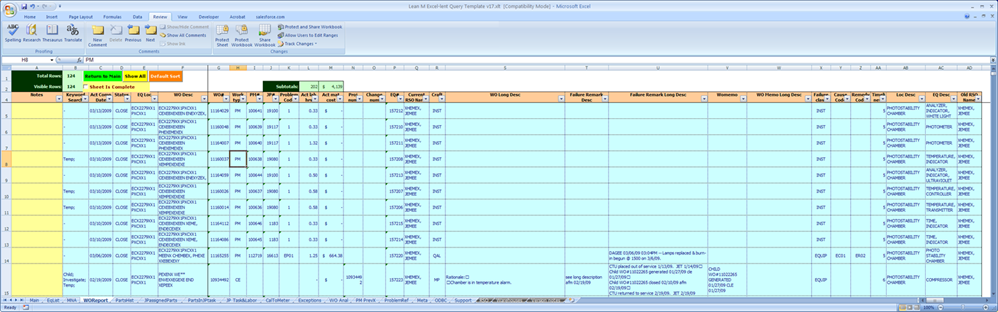

| The Work Order Report worksheet: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

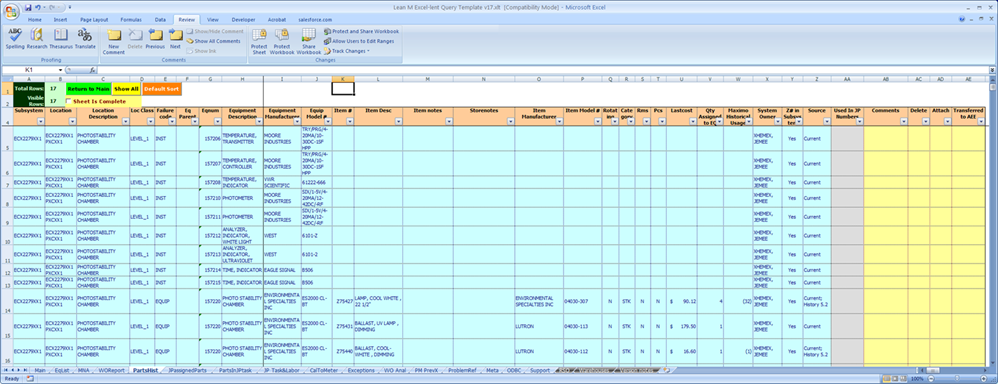

| Parts History worksheet: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

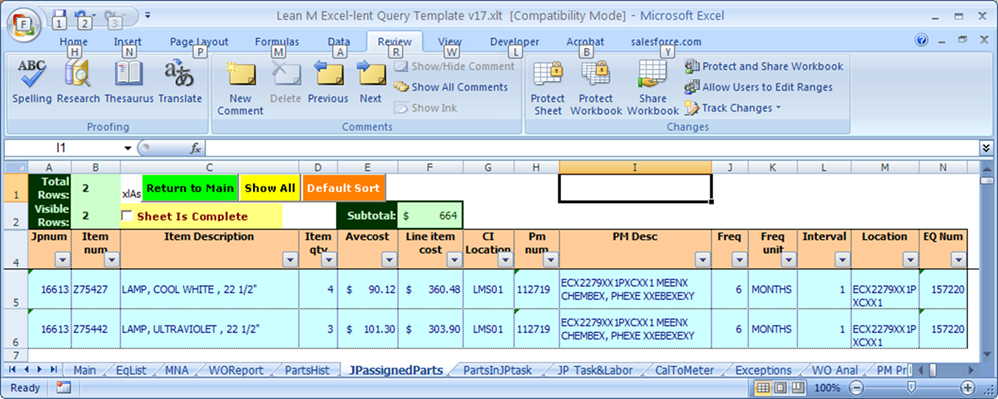

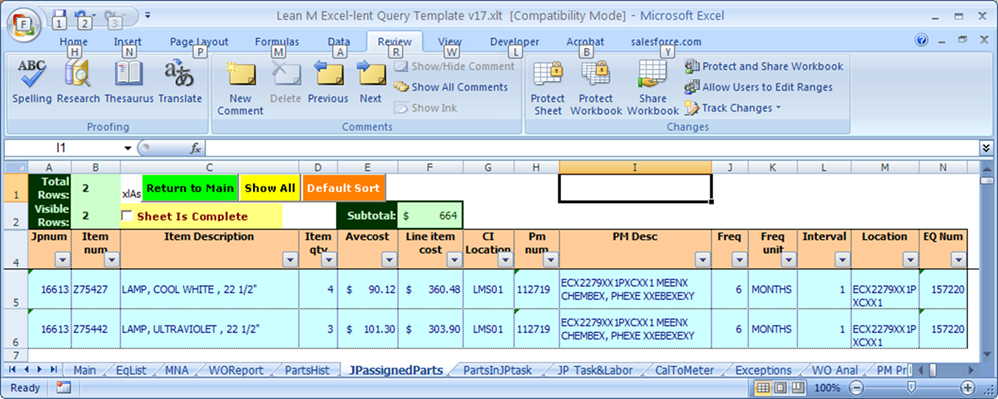

| Parts assigned to the associated Job Plans: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

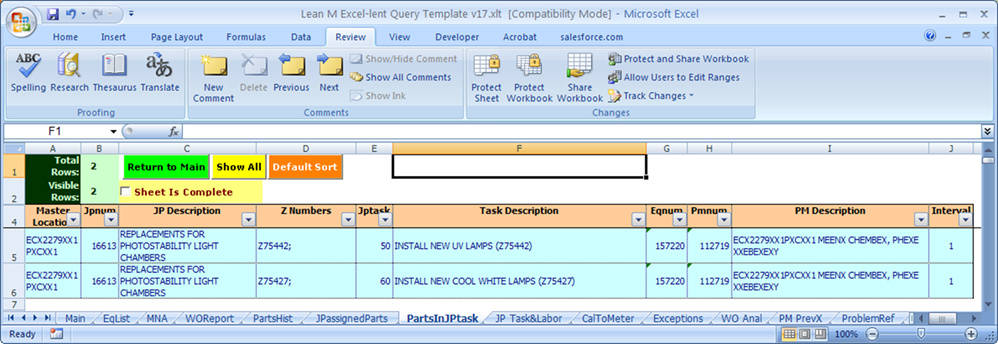

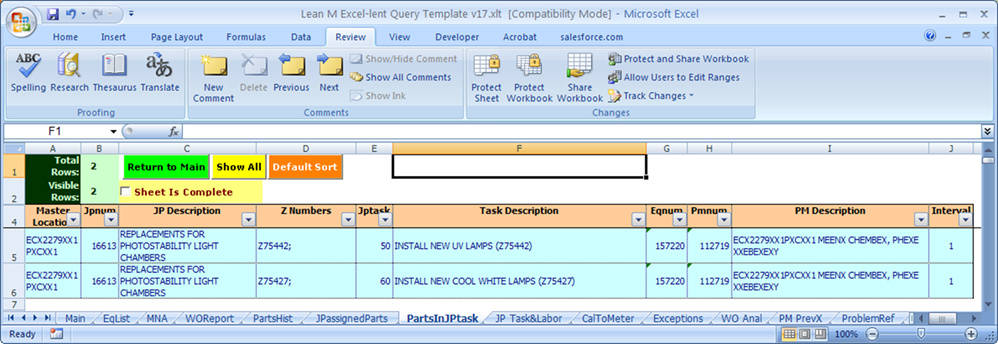

| An alternate view of Parts in Job Plans: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

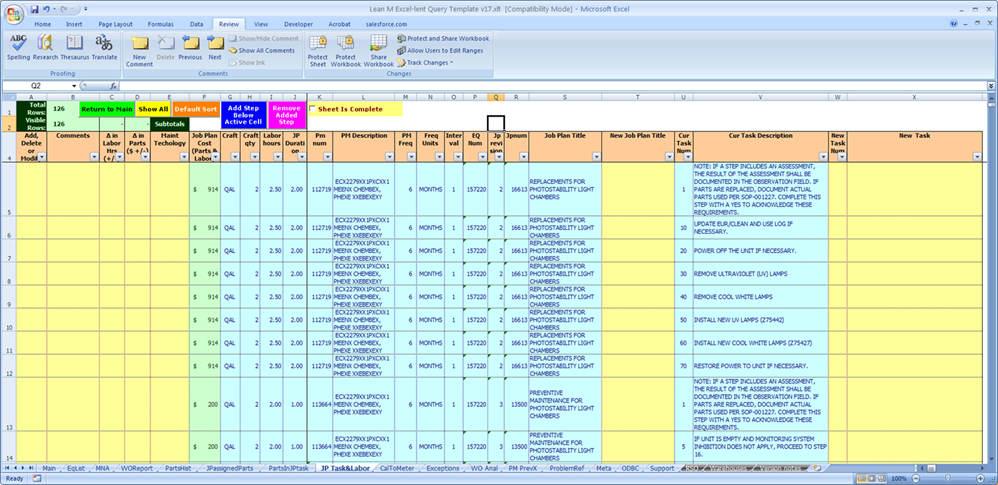

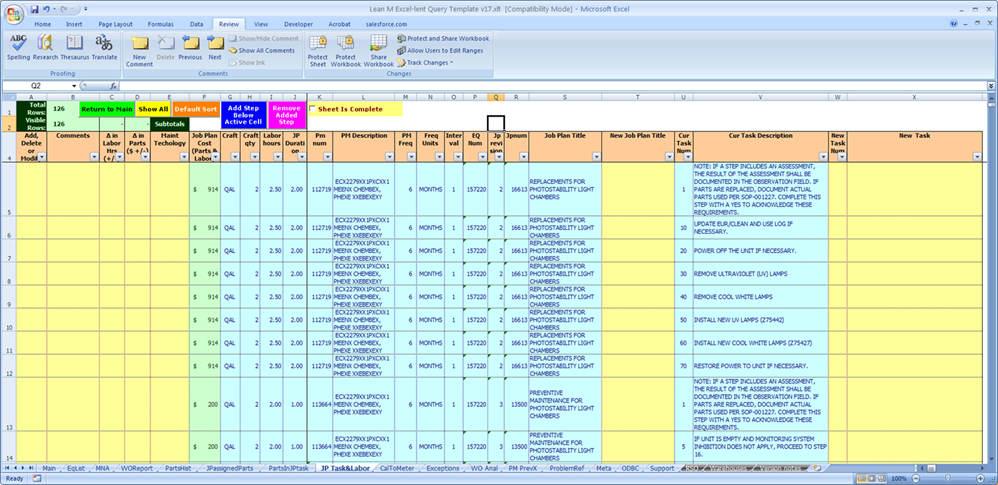

| A Job Plan task and labor report: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| In many cases it is more cost effective to schedule preventative

maintenance based on equipment usage (e.g. change the filter after every

1,000 hours or usage) instead of calendar time (every 6 months). The worksheet assists the system owner in

making that assessment: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

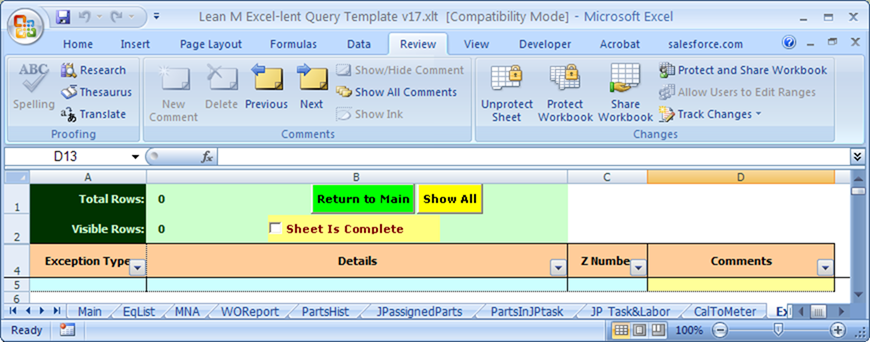

| If the software finds a problem, then a

line is added to the Exceptions worksheet (this is a bad example, there are

no exceptions!): |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

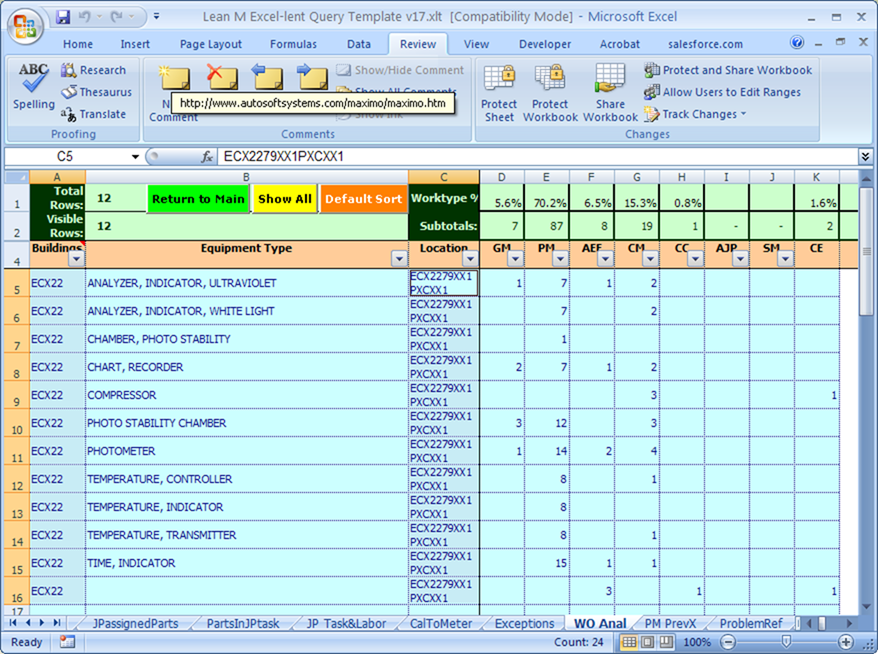

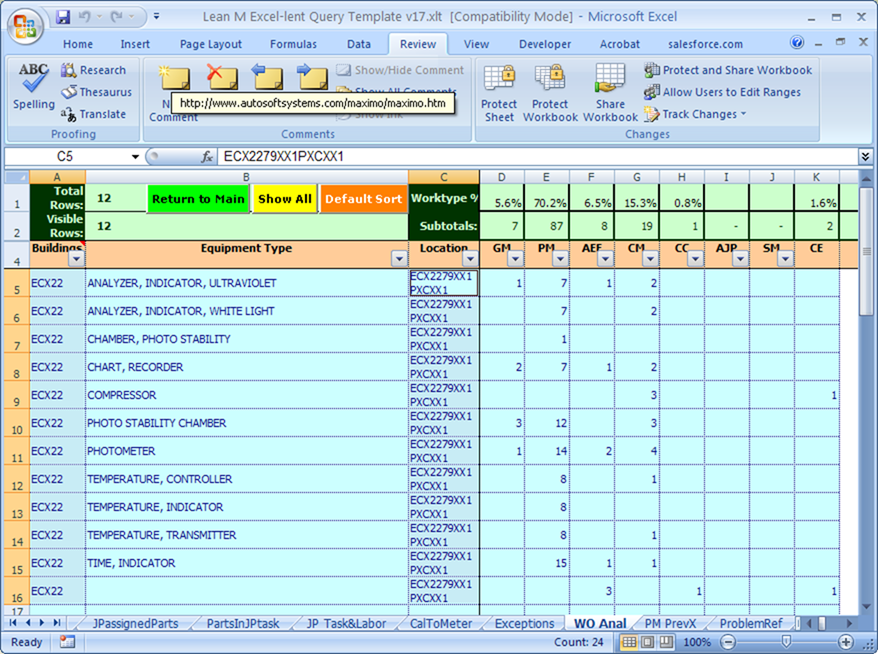

| The Work Order analysis worksheet lists

all of the work orders of every type that have occurred on the subsystem

being analyzed: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| A listing of problem codes is included for easy reference: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

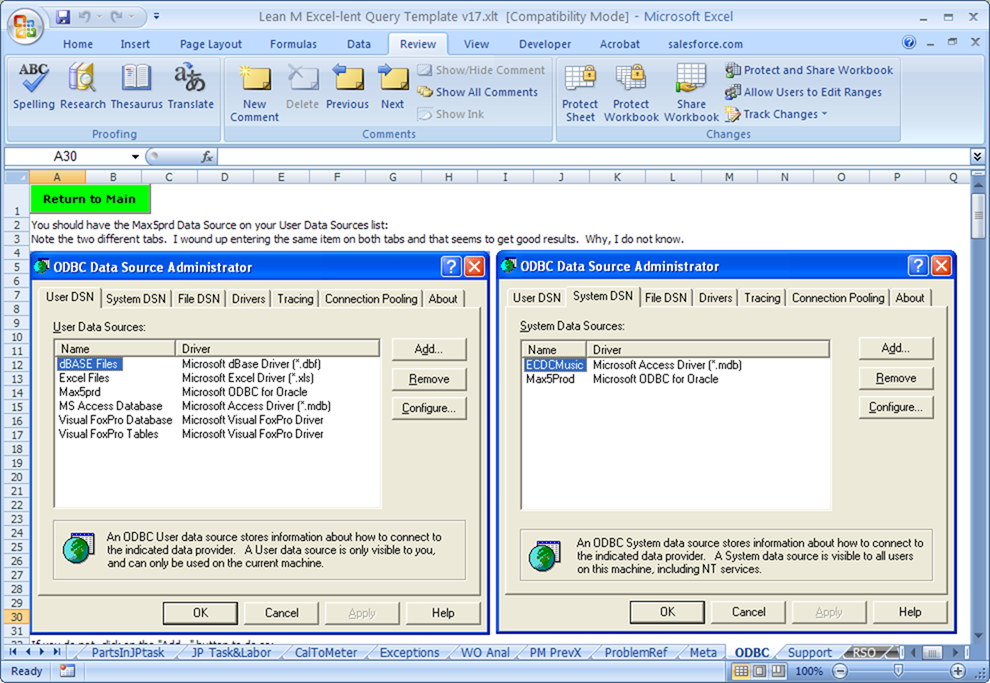

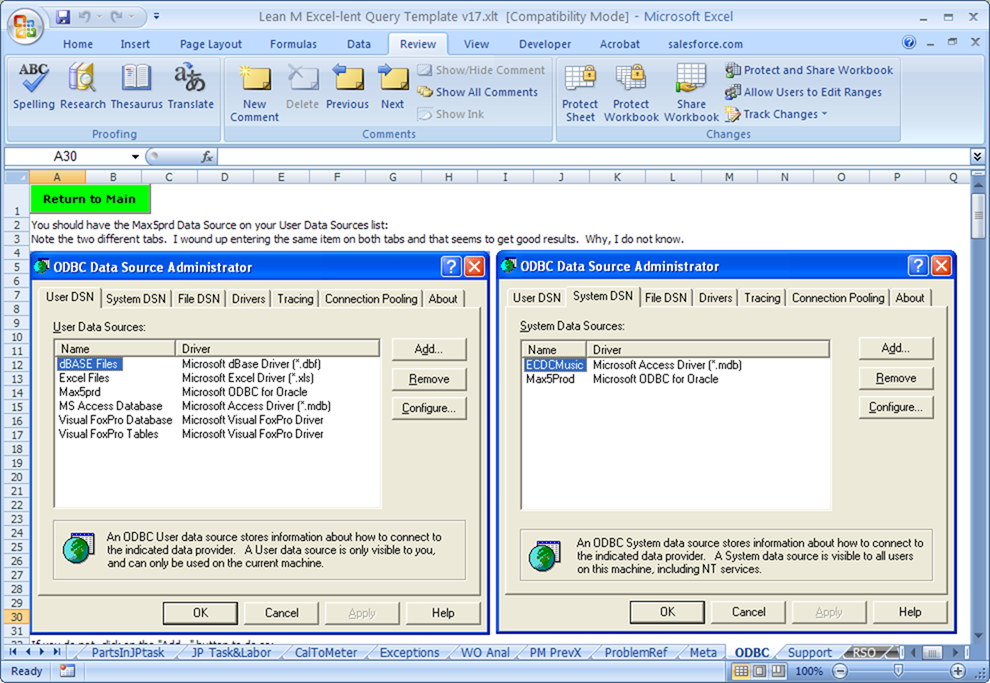

| Instructions are provided to allow the users to establish their

own ODBC connections: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

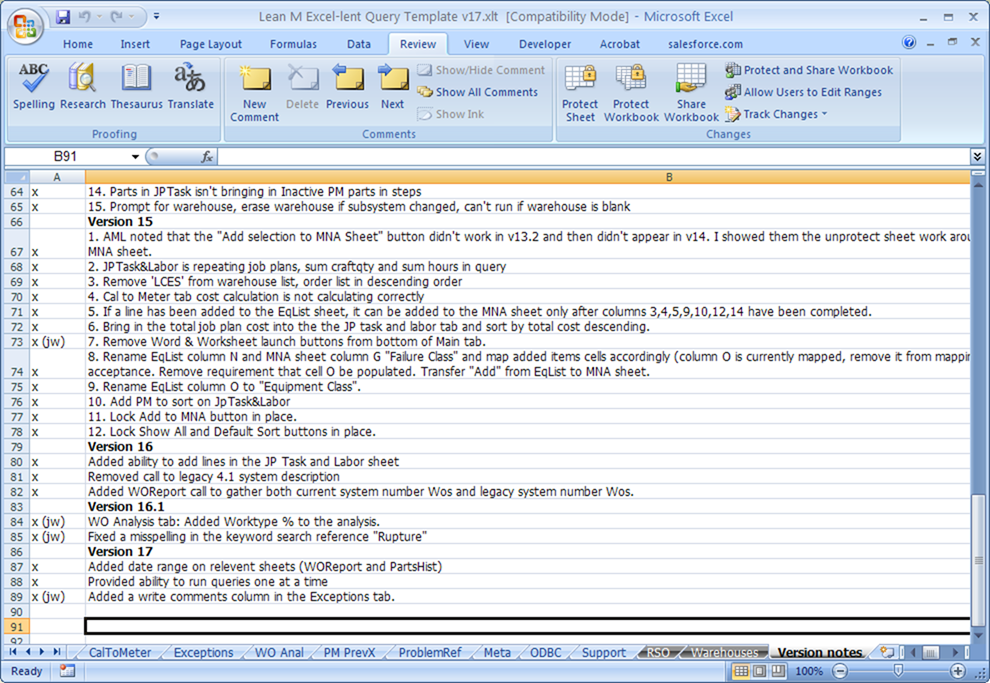

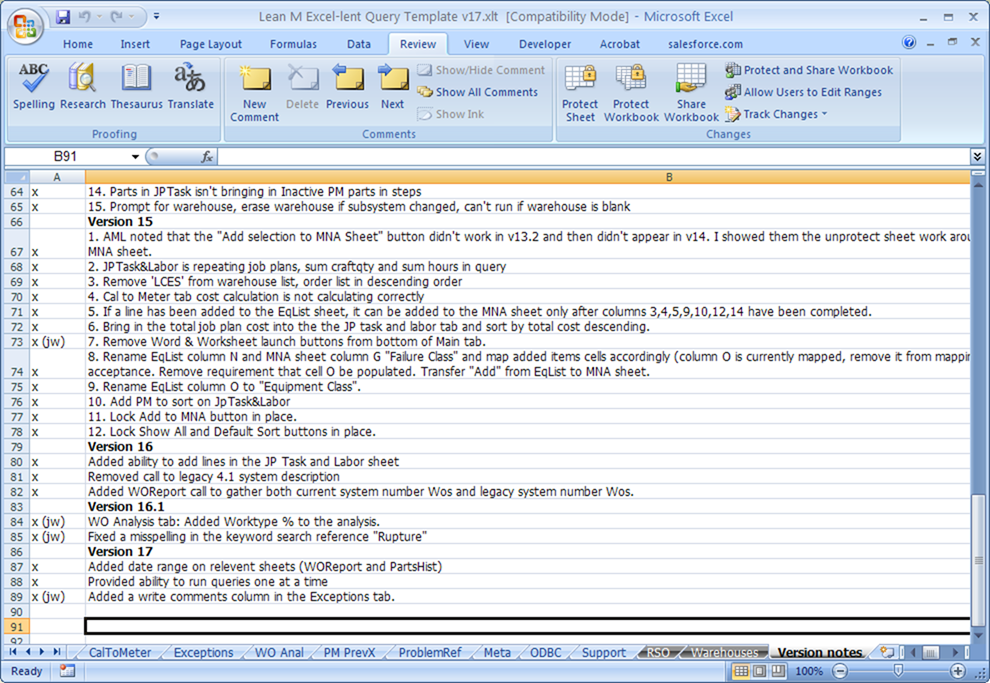

| Revision Notes are included as well: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| AutoSoft Systems | 2 Round Hill Court, East

Greenwich, Rhode Island, USA 02818 | 401.885.3631 | Fax: 401.884.5653 |

Mobile: 401.996.3631 |

| This web page was last updated at 02/21/2014 07:52 AM and is

written in EXCEL! |

| AXIOM is a Trademark of Consona - USYS is a Trademark of Zumbach

- AutoSoft Systems is not affiliated with Consona nor Zumbach |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![MCPE01984_0000[1]](subsystem_files/index_0000_image004.png)