|

|

|

|

|

|

|

|

|

|

|

|

AutoSoft Systems |

| |

|

|

|

AutoSoft

Systems |

2 Round Hill

Court |

| |

|

|

|

East Greenwich,

RI 02818 |

| |

|

|

|

401.885.3631 |

| |

|

|

|

401.884.5653 Fax |

| |

|

|

|

|

|

|

|

|

|

|

|

401.996.3631 Cell |

| AMDG |

|

|

|

Decision Ready

Information! |

autosoft@aol.com |

| Commercial & custom multi-user computer software for a

variety of applications including performance metrics, statistical analysis,

data extraction and merger from multiple large databases, computer simulation

and management information systems.

Founded in 1982. |

| We know Excel! Whenever possible, Excel

is the user interface, VBA is the programming language, ODBC connects to the

database of your choice. |

| Home |

About Us |

Literature |

Wire

& Cable |

Pharmaceutical

& Biotech |

Construction

Management |

Commercial

Products |

Custom Solutions |

| Contact Us |

Events |

Downloads |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AMDG |

| AutoData

Process and Lab Information Management System |

| AutoData is a fully functional

Lab Information Management System [LIMS] for small workgroups (< 20

users). In addition, through the use of data acquisition hardware, AutoData

can incorporate process information into the same data base to allow for integrated

analysis of both process and lab data. |

| View

AutoData's Complete Instruction Manual (> 3 MBs) |

| |

AutoData is password protected, and provides multiple levels of

user access. |

| |

AutoData stores data on one or more servers, but allows each

user to operate independently. |

| |

Data entry is

quick and only 3 entry fields are required: |

● Sample/Product ID |

|

|

| |

|

|

|

|

|

● Test

Method/Attribute |

|

|

| |

|

|

|

|

|

● Result |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

The user has the

option to pre-define additional fields: |

● Sample/Product

description |

|

|

| |

|

|

|

|

|

● Unit of

measure |

|

|

| |

|

|

|

|

|

● Specifications

(alarm & control limits) |

|

|

| |

(Additional

optional fields are available.) |

|

|

|

|

|

|

|

|

|

|

| |

The user has the option to display all pre-configured

specifications for a given Sample/Product. |

| |

Lookup functions assist the user in pinpointing a Sample/Product

or Test Method. |

| |

Extensive reports are available and can be view on-screen,

printed, or written to disk. |

| |

Automatic graphing of results is fully integrated with

Microsoft's ExcelŽ. |

| |

Site customization is available at fixed price quotes. |

| |

Source code is available. |

| |

Data acquisition

is through industry standard 4-20 milliamp and/or 0-10 VDC protocols. |

|

|

|

|

|

|

| |

One example of this is Thomas Engineering's

Compu-Lab. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Data Entry Screen: |

|

|

|

|

|

|

|

|

|

|

| Here the user first selects an IC Number (an Inventory Control

Number, a unique identifier of the item being tested, these are defined by

the user and can be any alpha-numeric identifier). Once the IC Number is

entered, a longer pre-defined description appears (in this case "Edible

Tallow"). The F5 button allows the user to search through the data base

if the IC number is not known. The lot number can then be optionally entered.

A date and time stamp is applied to the sample. The user then must identify

what test is being performed. Again these are all defined by the user. One or

many attributes can be assigned to each test method, which can be

quantitative or qualitative. The user then enters the test results in the

lower left grid, and the specification for each result appears at the lower

right. The equipment type and equipment can be optionally entered, and some

detailed notes can be entered as well. The user then clicks the desired

button in the upper right and the entry operation is complete. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Graphical Results Screen: |

|

|

|

|

|

| This screen is an example of the Microsoft Excel graph that

AutoData automatically generates. The user simply identifies the sample,

result, and date range desired, and with one click, AutoData searches the

data base for all matching entries, opens Microsoft Excel, imports the data

into Excel, and the AutoData.xlt template automatically generates the above

graph. Here, the blue dots represent the actual data points. The heavy blue

line represents the running average. The thin blue lines represent the running

deviation (2 sigma). The red lines represent the upper and lower control

limits. The purple lines represent the upper and lower alarm limits. This

file is a standard Excel file and can be further manipulated and saved by the

user if so desired. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| This screen is generated in a similar fashion to the prior

chart. Here, the blue line is a histogram the actual data points. The solid red lines represent the upper and

lower control limits, and dotted red lines represent the alarm limits. The

thin dotted lines represent a 1 sigma and 3 sigma distribution. This allows the user to rapidly determine

how well the actual process is conforming to a standard distribution

function. This file is a standard Excel file and can be further manipulated

and saved by the user if so desired. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Inventory: |

|

|

|

|

|

|

| There is an inventory module that allows for rapid sorting and

retrieval of information. |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

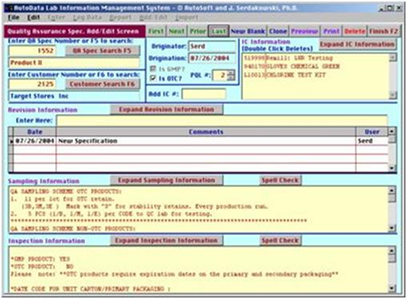

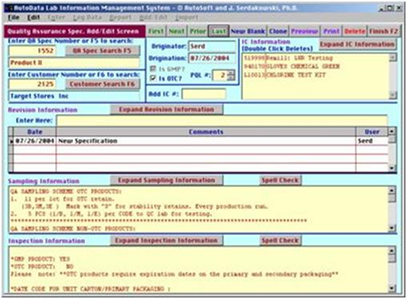

| Quality Assurance Specifications: |

|

|

|

|

|

|

|

| A flexible and

comprehensive Quality Assurance module is included: |

|

|

|

|

|

|

| AutoData can be leased for a low installation fee that includes

on-site training and configuration, and a monthly fee that includes unlimited

technical support and upgrades. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| AutoSoft Systems | 2 Round Hill Court, East

Greenwich, Rhode Island, USA 02818 | 401.885.3631 | Fax: 401.884.5653 |

Mobile: 401.996.3631 |

| This web page was last updated at 02/21/2014 07:56 AM and is

written in EXCEL! |

| AXIOM is a Trademark of Consona - USYS is a Trademark of Zumbach

- AutoSoft Systems is not affiliated with Consona nor Zumbach |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|