|

|

|

|

|

|

|

|

|

|

|

|

AutoSoft Systems |

|

|

|

|

| |

|

|

|

AutoSoft

Systems |

2 Round Hill

Court |

|

|

|

|

| |

|

|

|

East Greenwich,

RI 02818 |

|

|

|

|

| |

|

|

|

401.885.3631 |

|

|

|

|

| |

|

|

|

401.884.5653 Fax |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

401.996.3631 Cell |

|

|

|

|

| AMDG |

|

|

|

Decision Ready

Information! |

autosoft@aol.com |

|

|

|

|

| Commercial & custom multi-user computer software for a

variety of applications including performance metrics, statistical analysis,

data extraction and merger from multiple large databases, computer simulation

and management information systems.

Founded in 1982. |

|

|

|

|

| We know Excel! Whenever possible, Excel

is the user interface, VBA is the programming language, ODBC connects to the

database of your choice. |

|

|

|

|

| Home |

About Us |

Literature |

Wire

& Cable |

Pharmaceutical

& Biotech |

Construction

Management |

Commercial

Products |

Custom Solutions |

|

|

|

|

| Contact Us |

Events |

Downloads |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AMDG |

|

|

|

|

| General Electric - Substation

Transformer Auxilary Cooling |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| General Electric had a problem.

They were selling an auxiliary heat exchanger for substation

transformers, but the control system just could not perform as desired. Their “Version 1” control system consisted

of a custom designed and proprietary hardware and software solution that was

limited in functionality and difficult to upgrade, maintain and

configure. The product’s sales manager

was frustrated because he knew that he could sell more systems if the

functionality were improved. He was

familiar with Dr. Serdakowski’s work, and invited Dr. Serdakowski to present

a proposal to General Electric’s engineers.

The proposal was accepted, and the rest is history. |

|

|

|

|

| This example demonstrates Dr. Serdakowski’s abilities to design

a control system. In addition, Dr.

Serdakowski prepared a computer simulation of this problem that is used by

both GE design engineers and GE sales engineers. The details of the simulation are discussed

at the bottom of this page. |

|

|

|

|

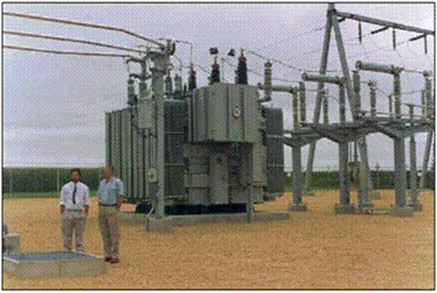

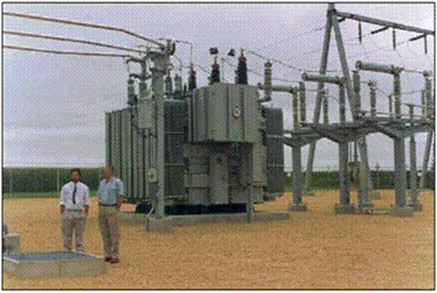

| Substation transformers are large devices (see image to the

right) that weight tens of thousands of pounds (empty). They are filled with tens of thousands of

gallons of heat transfer fluid.

Although they are typically 99.8% efficient in the transforming of

electricity from one voltage to another, processing hundreds of Mega

Volts-Amps of electricity force the liberation of hundreds of BTUs per

second. Overheating of a multi-million

dollar transformer will shorten its life span. The addition of an auxiliary heat exchanger

to take additional heat out of the heat transfer fluid is a cost effective

method of extending the life and capacity of the transformer. Caution is advised however, since cooling

the heat transfer fluid too much will result in a change of state with the

fluid becoming conductive. GE markets

this auxiliary heat exchanger under the name TransCool, and these units cost

less than $100,000, a small fraction of the cost of a new transformer. |

|

|

|

|

|

|

|

|

|

|

|

| The industrial computers from SmallPC running Windows XP Pro

were selected for the hardware.

Advantech ADAM modules were selected for the analog to digital

converters. The AutoControl

application framework was selected for the software. AutoControl has four components. General Electric’s implementation of these

components (named TransCool) is as follows: |

|

|

|

|

| Configure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The Configure program will run on any Windows computer (laptop

or desktop). Before launching

Configure, the process engineer establishes a phone link with the TransCool

computer using standard Windows networking protocols. |

|

|

|

|

|

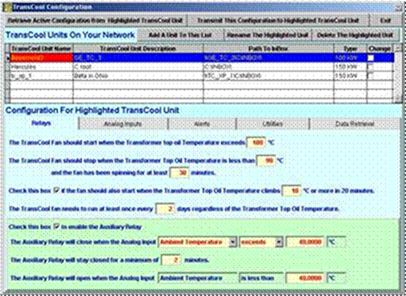

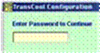

| Upon startup, the Configure program requires a password: |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

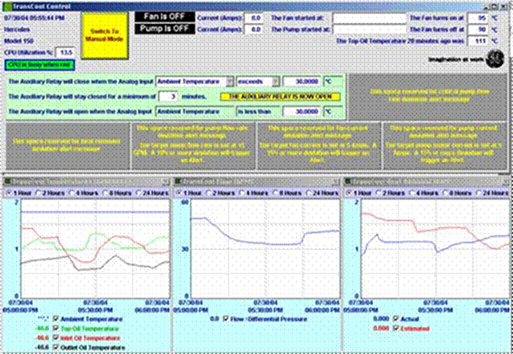

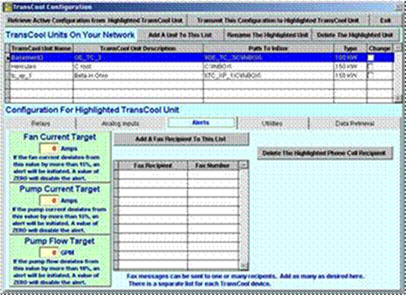

| The main screen: |

|

|

|

|

|

|

|

|

|

|

|

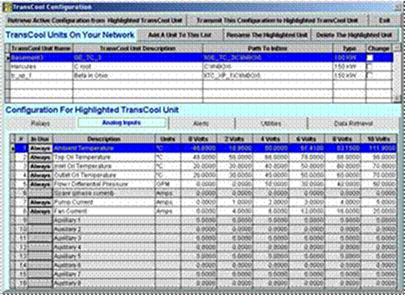

| An unlimited number of TransCool units can be configured from

this software. The top half of this

screen manages the units and the transmittal of configuration data to and

from the units. The bottom half

controls the configuration. Note how

configuration is a simple as “fill in the blanks”. |

|

|

|

|

|

|

|

|

|

|

|

| The Analog Input screen controls the calibration of up to 16

analog inputs. Dr. Serdakowski is a

fan of a 6 point polynomial calibration scheme he developed. It proved to be quite helpful in the 11th

hour when GE engineers realized that the flow meter was not linearized, and

the 6 point scheme was able to compensate. |

|

|

|

|

|

|

|

|

|

|

|

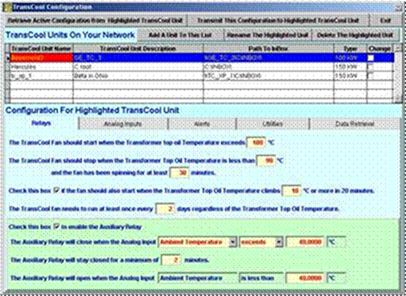

| The Alerts screen allows the process engineer to specify the

value of three critical parameters that would initiate a Fax of voice message

to one or more recipients. |

|

|

|

|

|

|

|

|

|

|

|

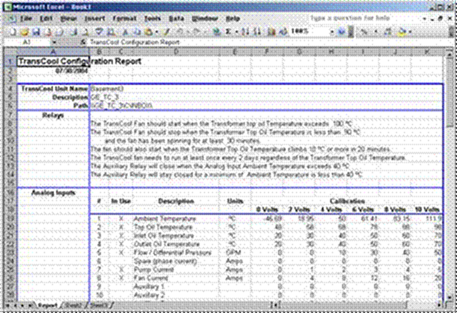

| The Utilities screen allows the process engineer to change the

password as well as generate a Microsoft Excel document that contains all

of the configuration information. |

|

|

|

|

|

|

|

|

|

|

|

|

| This is a screen shot showing a fraction of the configuration

report. |

|

|

|

|

|

|

|

|

|

|

|

|

| The Data Retrieval screen provides a simple and intuitive way of

retrieving data from the TransCool computer over a low-bandwidth

connection. Reports are generated as a

Microsoft Excel workbook that includes tables and graphs: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Control |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

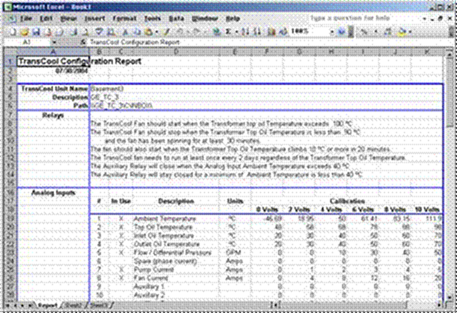

| The Control program runs 24x7x365 on the TransCool

computer. The user interface includes

the ability to toggle between manual and automatic mode, and three different

strip chart recorders. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| WatchDog |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The WatchDog program runs in the background. It occupies very little screen “real

estate”. It assures the Control

program is running correctly and updates the Control program when necessary. |

|

|

|

|

| Guardian |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The Guardian has no user interface. It runs periodically and checks to assure

both the Control and Watchdog programs are running correctly. |

|

|

|

|

| Computer Simulation of

the TransCool process |

|

|

|

|

|

|

|

|

|

|

|

|

|

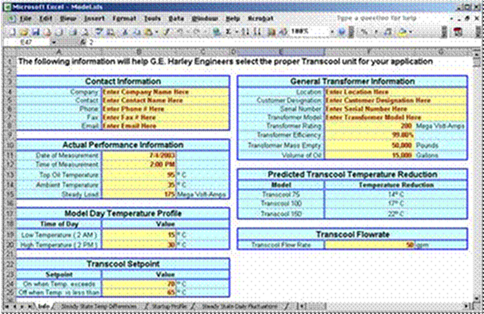

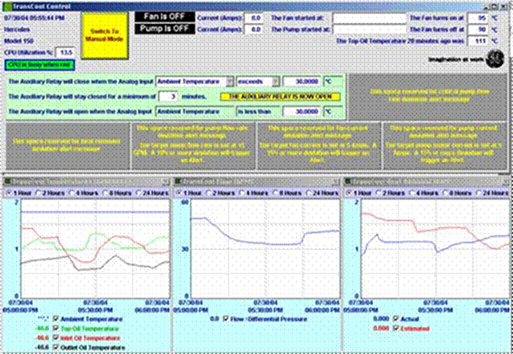

| Dr. Serdakowski prepared an Excel spreadsheet that simulates

the temperature of a transformer with and without a TransCool attached to

it. This model is used as both a

simulation tool to help GE engineers better understand the effects of a

TransCool. The model is also used by

GE sales engineers to explain to the customers how the TransCool unit

reduces the temperature of the transformer and extends the life of the

transformer. |

|

|

|

|

|

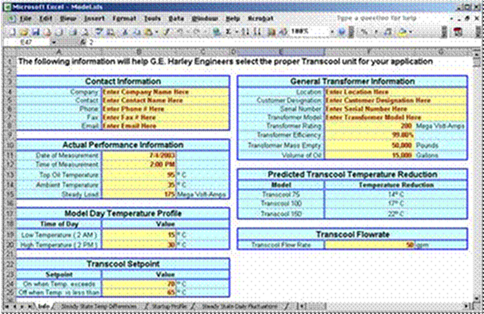

| This is the input screen.

The GE engineers enter the parameters for the transformer to be

evaluated in the yellow boxes. |

|

|

|

|

|

|

|

|

|

|

|

|

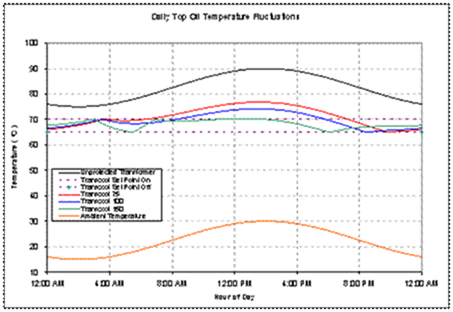

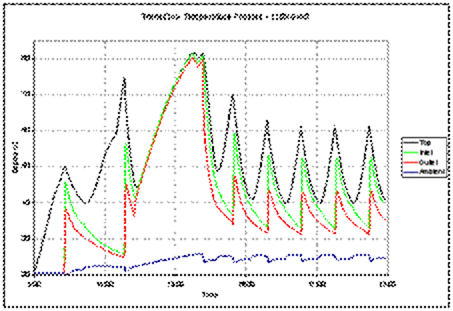

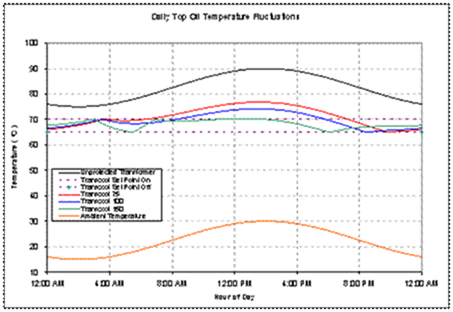

| This output shows the temperature profile experienced by an

unprotected transformer and transformers protected by 3 different TransCool

systems. Note that in this case, only

the TransCool 150 is large enough to maintain the temperature of the

transformer within the desired operating range. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| This graphic by itself is quite noisy and requires some

explanation. It is from a PowerPoint

presentation and was designed to be displayed 1 image at a time with a verbal

description to accompany each step. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The substation transformer has a TransCool heat

exchanger attached to it. |

|

|

|

|

|

| A series of temperature probes generate 4-20 milliamp output signals

which pass through an Advantech ADAM analog input module. |

|

|

|

|

|

| An embedded Windows XP Pro computer records the temperatures and

signals an Advantech ADAM relay module to operate a series |

|

|

|

|

|

| of switches that control pumps, fans and local

alarms. |

|

|

|

|

|

| Three software programs written by Dr. Serdakowski assure 24x7x365

operation. |

|

|

|

|

|

| The embedded computer can be accessed remotely by an

engineer running a fourth

program to configure

operation and download performance data into Excel. |

|

|

|

|

|

| The embedded computer will also send out periodic and emergency

emails, faxes and phone calls. |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| AutoSoft Systems | 2 Round Hill Court, East

Greenwich, Rhode Island, USA 02818 | 401.885.3631 | Fax: 401.884.5653 |

Mobile: 401.996.3631 |

|

|

|

|

| This web page was last updated at 04/30/2014 01:15 PM and is

written in EXCEL! |

|

|

|

|

| AXIOM is a Trademark of Consona - USYS is a Trademark of Zumbach

- AutoSoft Systems is not affiliated with Consona nor Zumbach |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|